Implicit modeling for in-place robotic 3D printing

This article presents the outcome of my master’s thesis for the Master of Advanced Studies ETH in Architecture and Digital Fabrication, supervised by Inés Ariza and Mathias Bernhard. This investigation focused on the use of implicit modeling tools for the design of fabrication-informed three-dimensional print paths for in-place spatial additive manufacturing.

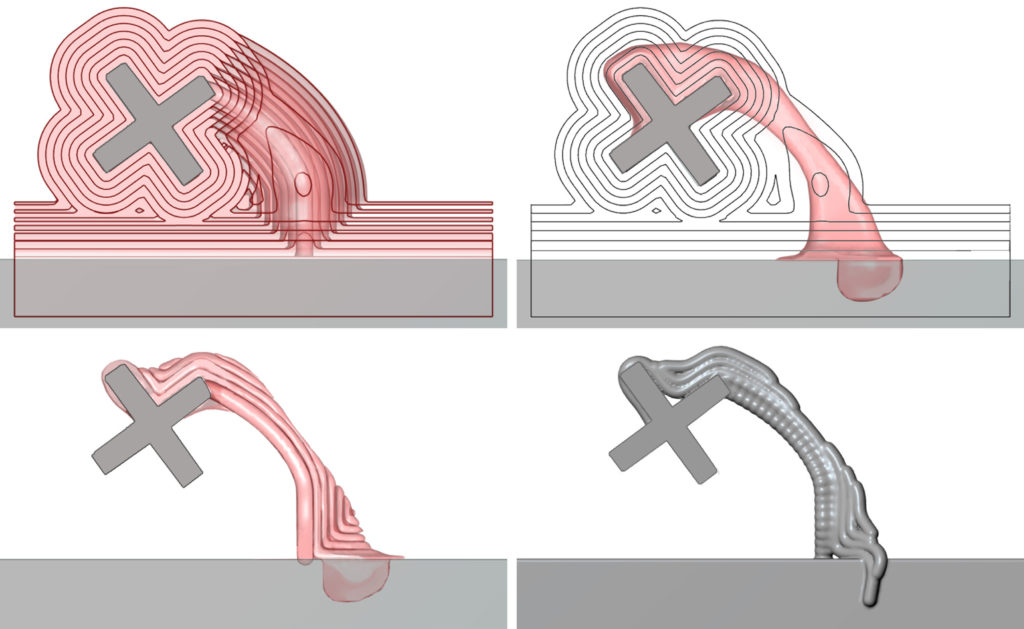

Implicit modeling allows designing with great geometric flexibility using mathematical functions and numeric data. We investigated how to incorporate fabrication constraints using implicit modeling, focusing on the unique constraints inherent to in-place spatial additive manufacturing. To this end, we devised a set of computational tools tailored to design deposition paths that allow embedding fabrication constraints. As a case study, we implemented this toolset to create wire arc additive manufacturing (WAAM) connections of standard elements with arbitrary orientations, that can be used to assemble non-standard architectural space frames.

Acknowledgments

Supervisors:

Inés Ariza, Gramazio Kohler Research, ETH Zurich

Mathias Bernhard, Digital Building Technologies, ETH Zurich

This work is embedded within the broader context of current research on In-place detailing (Ariza et al. 2018) and Volumetric modeling for 3D printed architecture (Bernhard et al. 2018). The findings of this work are summarised in the publication: Numerical Sculpting: Volumetric modelling tools for in place spatial additive manufacturing (Mitropoulou et al. 2019).