FDM 3d printing, concrete casting

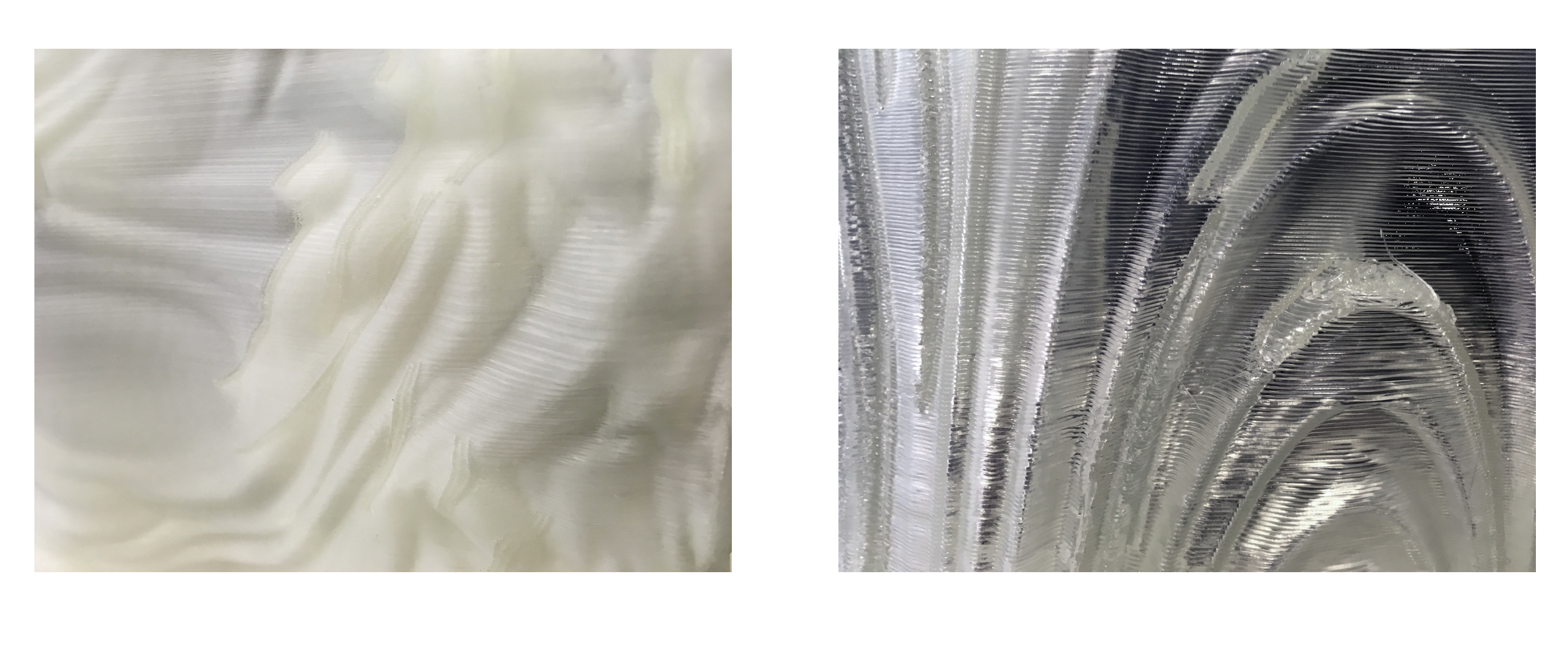

In this project we were challenged to investigate the unprecedented design freedom in casted concrete components promised by the advent of large scale 3D printing fabrication processes. The materials we used was translucent PLA for the 3D printed formwork, and fiber-reinforced concrete.

We worked on strategies for integrating both of those materials in the final product in order to produce translucent concrete components. This is achieved by preinstalling light shafts on the formwork, that remain on the mass of the concrete component after the formwork is removed.

The design was achieved through parametric modelling where the fabrication constraints where gradually integrated through experimentation with the technique. The morphology of the surfaces and the position of the light shafts are determined computationally using primarily Fractal Brownian Noise.

In collaboration with Alexander Enz & Matteo Lomaglio, ETH dFab

Photo Credit: Tom Mundi