FabLab prototyping, Arduino automation

This project is a research on kinetic architectural elements, and an experimentation on the interaction of the human with the architectural shell.

The interest is set on achieving smooth, user-friendly and low-energy movement by using a smart geometrical configuration, on creating a parametric model that allows for customisation, and on issuing a fabrication line so that almost all the necessary parts can be prototyped and created within a FabLab, thus making the assembly of the mechanism equally accessible to everyone.

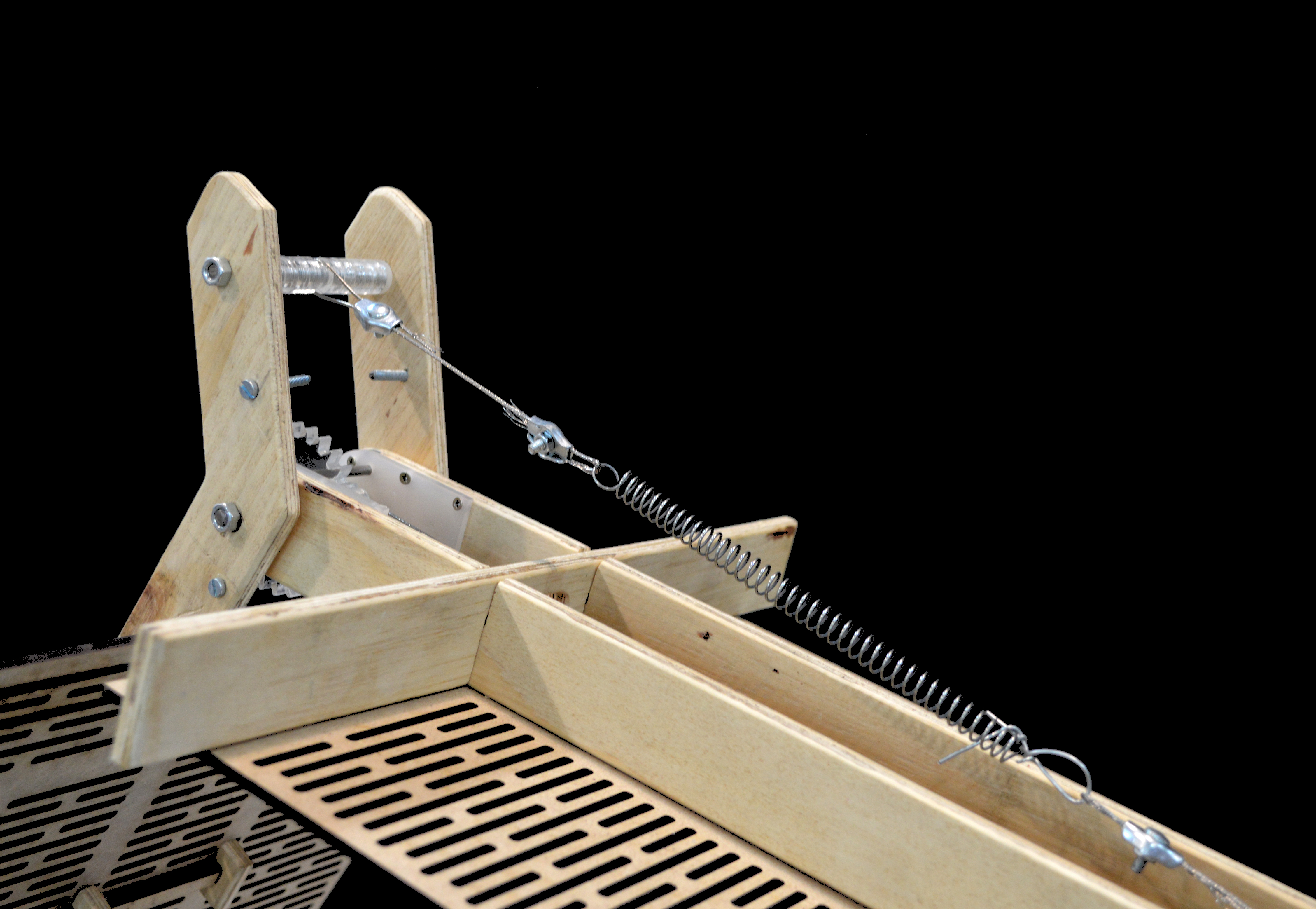

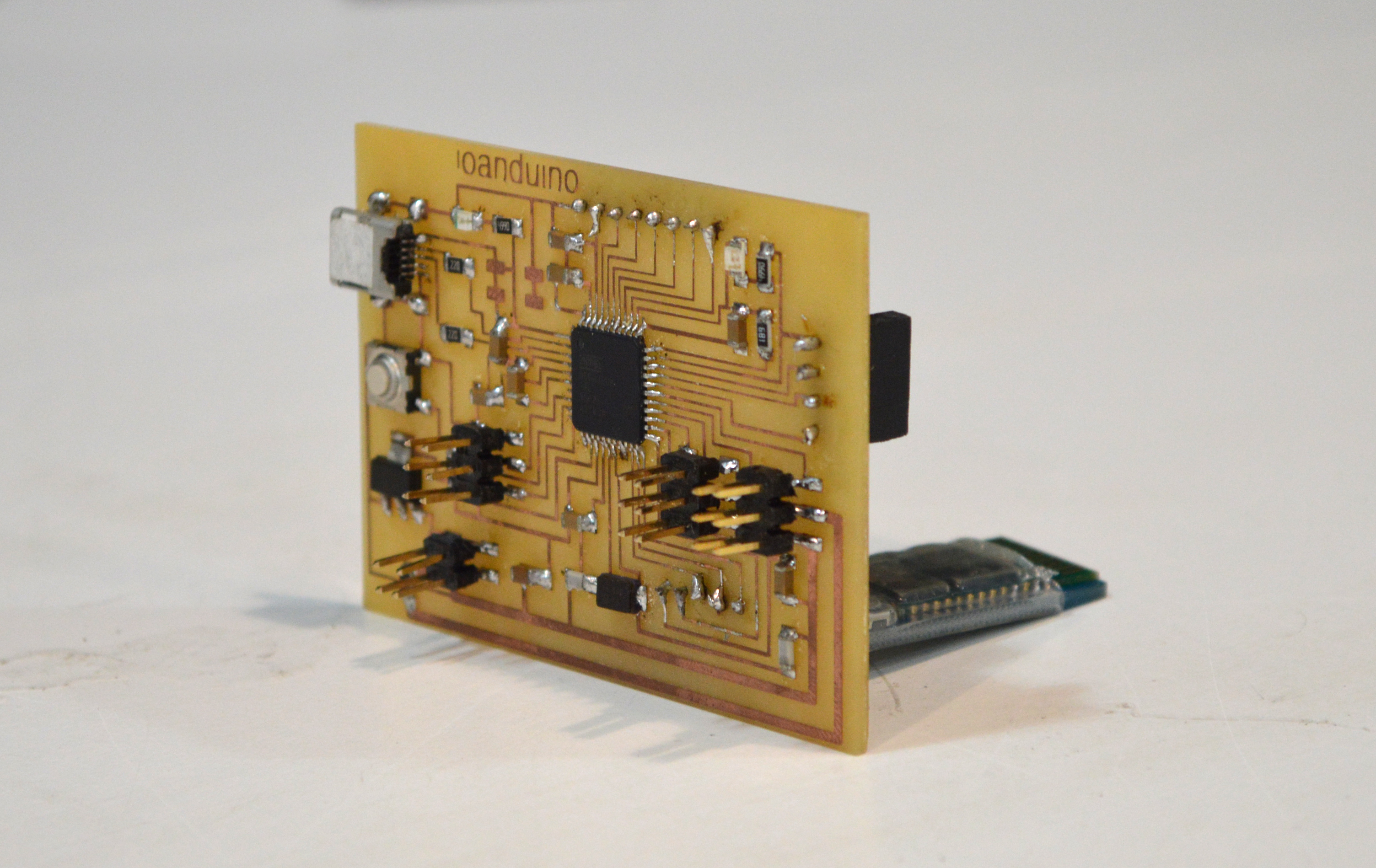

A prototype of a kinetic panel was developed that consists of two arms and uses spring forces as counterweights to achieve smooth movement, and minimise energy requirements and reliance upon the actuators. The prototype is fully automated using a custom PCB (based on Arduino). Finally, the user can interact with the mechanism using his phone via bluetooth using the project’s application.

After the development of the prototype, two architectural proposals were formulated as show cases, that demonstrate the potential of such mechanisms.

The first is an open-plan office that uses kinetic panels installed on the ceiling, to achieve variable shading and space separation which can easily be customised by the users.

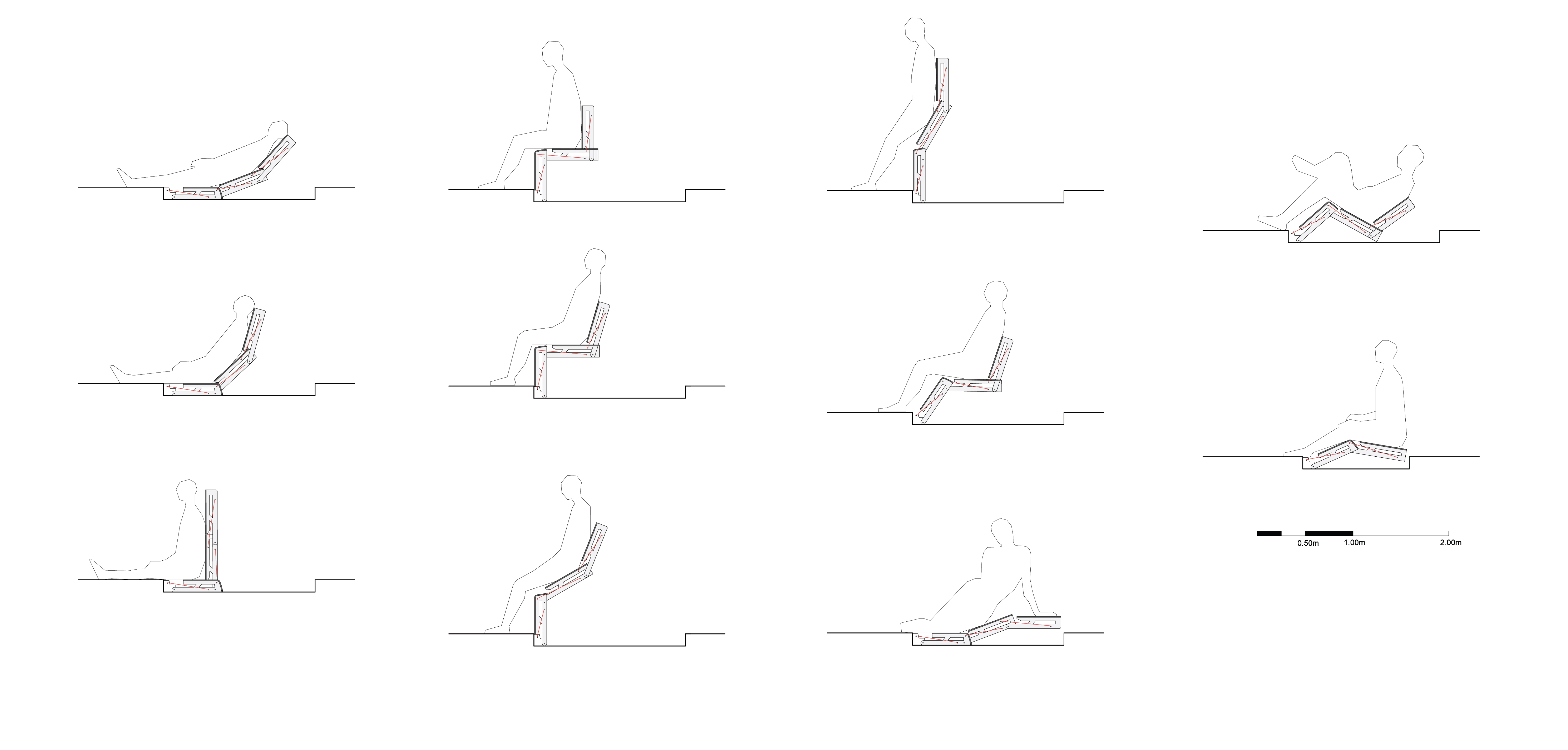

The second is an amphitheatre with the panels installed on the floor, that are used as moving platforms and as seats that can be customised for each user. The panels can be closed into the floor leaving a free flat space that can be used in multiple ways.

The prototype

Printed Circuit Board (PCB)

Architectural Proposals

Open-Plan Office

Amphitheatre

Personal Project

Supervisor: Giorgos Parmenidis

The first part of the project was developed at IAAC in the FabLab Barcelona. The project was completed in the National Technical University of Athens and was presented as my Diploma Project.